Grade A Cement-Based HPL Board

High-density inorganic core material with superior fire resistance

Quick Specifications

Product Overview

Grade A Cement-Based HPL Board is a high-performance inorganic panel manufactured using Portland cement, cellulose fibers, and mineral additives, compressed and cured under controlled conditions. The production process involves mixing cement with reinforcing fibers, forming sheets under pressure (80-100 kg/cm²), then autoclave curing at elevated temperature and pressure to achieve maximum strength and dimensional stability. The result is a completely non-combustible panel with Class A1 fire rating (EN 13501-1), zero flame spread, and zero smoke generation. The inorganic composition ensures zero formaldehyde emission and no VOCs, meeting the strictest environmental standards including LEED, WELL Building Standard, and Green Building certifications. High-density core (≥1.35 g/cm³) provides excellent sound insulation (STC 45-50) and impact resistance. Moisture-resistant formulation prevents swelling, warping, or delamination in humid environments. Available in thicknesses from 6mm to 12mm, specifically designed for modular partition systems, demountable walls, and areas requiring non-combustible, environmentally friendly construction materials. The lightweight nature (compared to gypsum board) facilitates easy installation and reduces structural load. Compatible with standard metal stud framing systems. Surface accepts paint, wallpaper, tile, or decorative laminates. Ideal for green building projects, office renovations, healthcare facilities, and educational institutions prioritizing indoor air quality and fire safety.

Technical Specifications

Physical Properties

| Thickness Range | 6mm - 25mm |

| Standard Sizes | 1200×2400mm, 1200×3000mm |

| Density | 1.0-1.2 g/cm³ |

| Flexural Strength | ≥15 MPa |

| Water Absorption | <5% (24h immersion) |

| Thermal Conductivity | 0.25-0.35 W/m·K |

Fire & Moisture Performance

| Fire Classification | Class A1 Non-Combustible |

| Flame Spread | 0 (non-combustible) |

| Smoke Development | 0 |

| Moisture Resistance | Excellent (outdoor rated) |

| Freeze-Thaw Cycles | >50 cycles |

| Mold Resistance | ASTM D3273 Score 10 |

Installation & Durability

| Screw Pull-Out | ≥1000 N |

| Impact Resistance | Good |

| Dimensional Stability | <0.3% linear change |

| Service Life | 50+ years |

Standards & Certifications

| ASTM C1325 | Fiber-Cement Board Standard |

| EN 12467 | Fiber-Cement Flat Sheets |

| ISO 9001 | Quality Certified |

Key Benefits

Non-Combustible

Class A1 fire rating, completely non-combustible

Waterproof

Impervious to water, suitable for wet areas

Mold Resistant

Inhibits mold and mildew growth

Lightweight

Easier handling and reduced structural load

Impact Resistant

Durable core withstands physical impacts

Fire Barrier

Provides fire compartmentalization

Dimensionally Stable

Minimal expansion/contraction

Easy to Install

Standard cutting and fastening methods

Real-World Case Studies

Proven Excellence in Global Projects

Dubai 2020 Expo

SUN PLUS HPL materials were used for outdoor cabinets and toilet partitions at the Dubai 2020 Expo, demonstrating excellent durability and weather resistance in high-traffic public spaces.

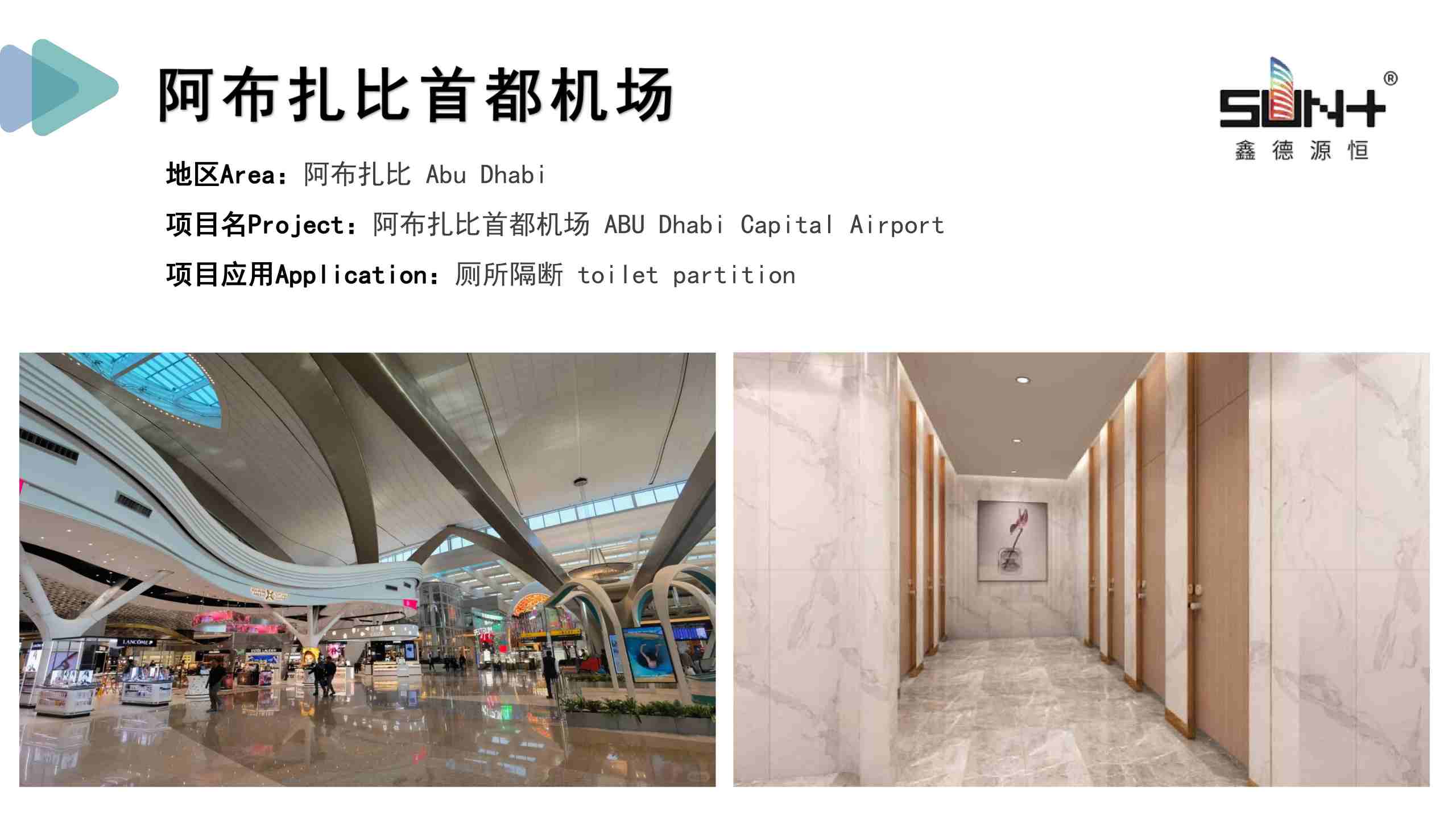

Abu Dhabi Capital Airport

Premium HPL partition systems were installed in Abu Dhabi Capital Airport's facilities, providing hygienic, durable, and easy-to-maintain surfaces for high-traffic airport environments.

Dubai Police Headquarters

SUN PLUS wall panels were selected for Dubai Police Headquarters, offering superior durability, fire safety, and professional aesthetics for government facilities.

Sharjah Police Headquarters

High-performance HPL partitions and cabinets were installed at Sharjah Police Headquarters, combining functionality with professional design for law enforcement facilities.

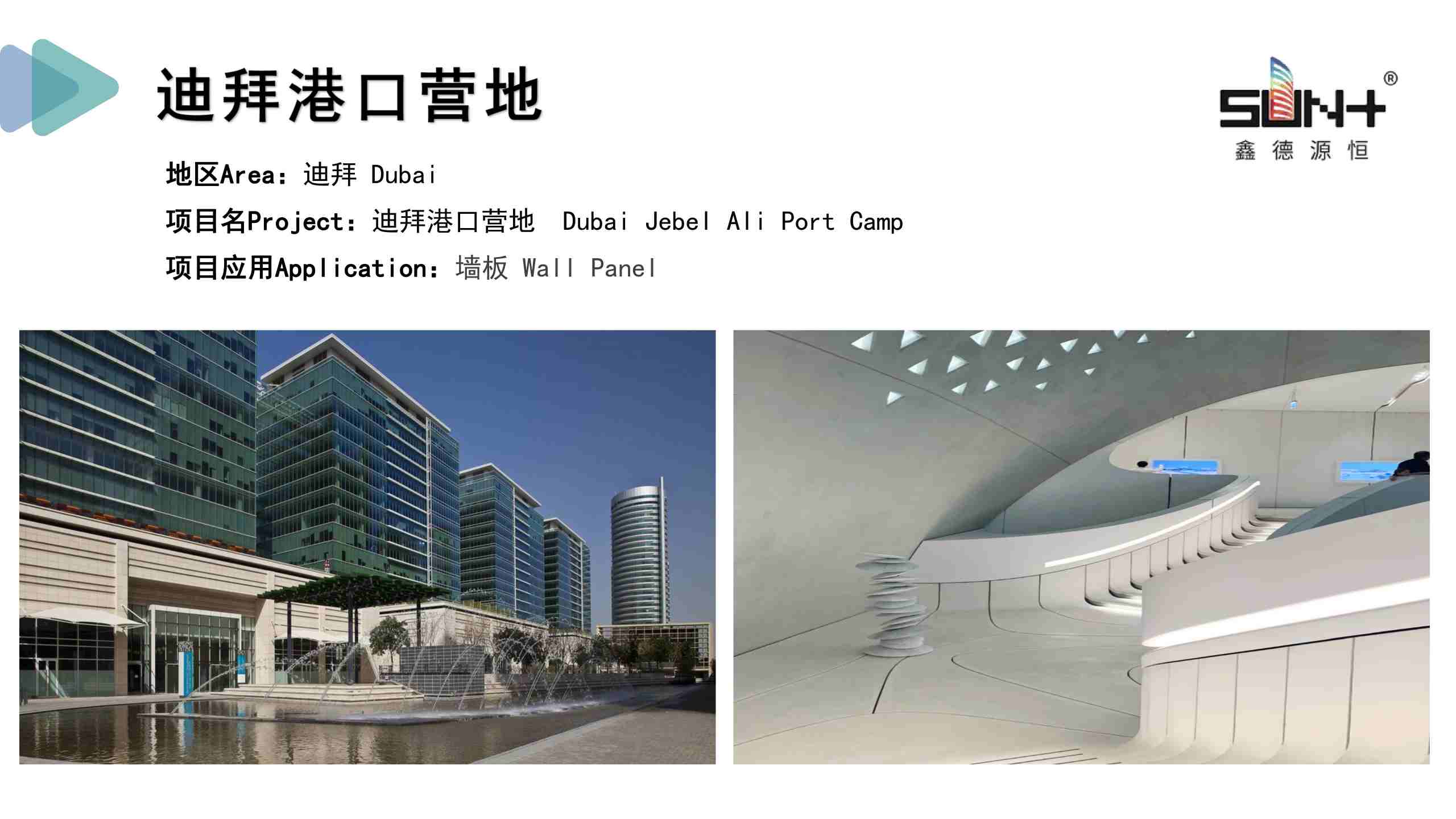

Dubai Jebel Ali Port Camp

Weather-resistant HPL wall panels were used at Dubai Jebel Ali Port Camp, providing excellent protection against harsh maritime and outdoor conditions.

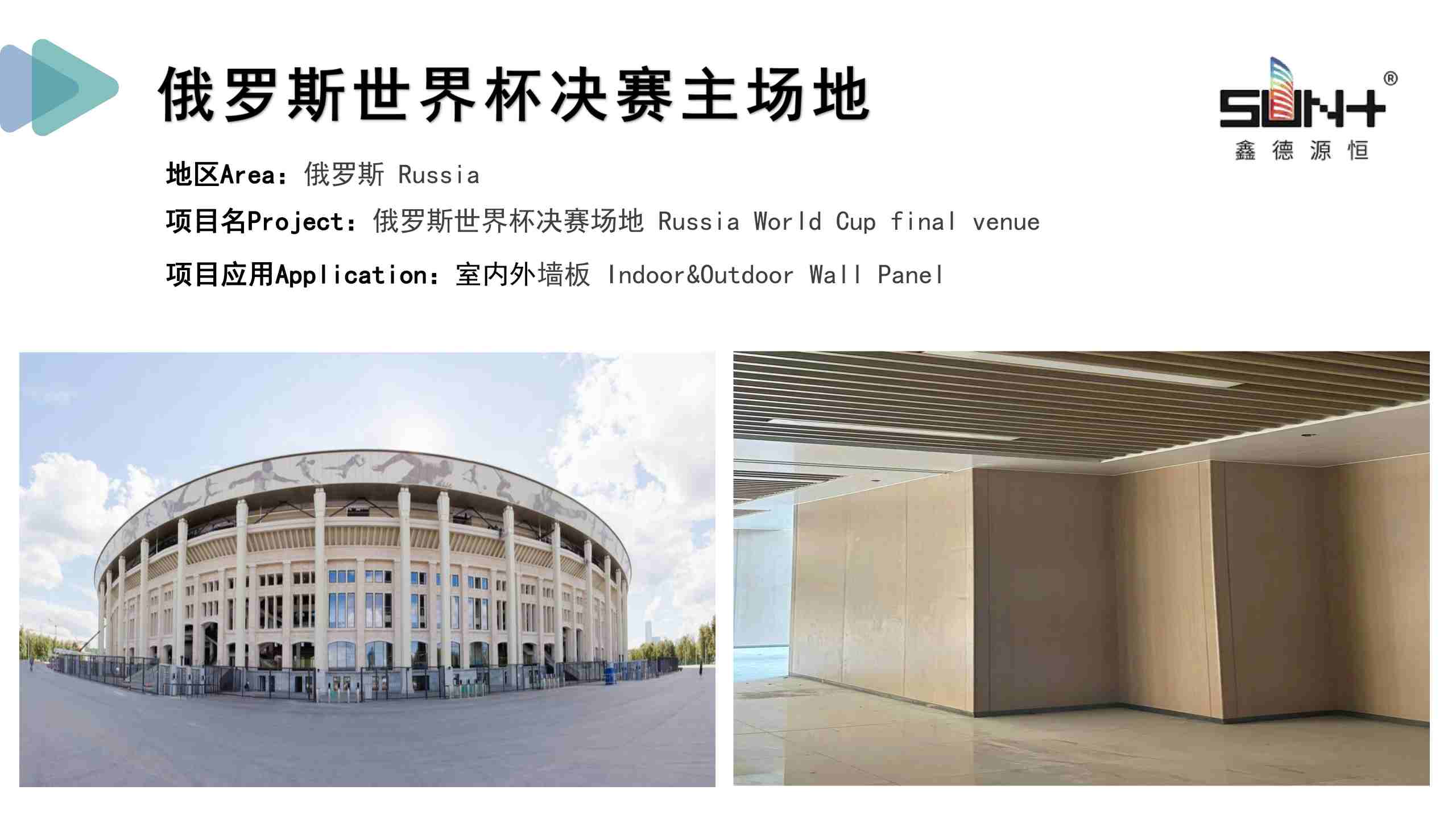

Russia World Cup Final Venue

SUN PLUS HPL materials were selected for the Russia World Cup final venue, meeting international standards for both indoor and outdoor applications with superior performance.

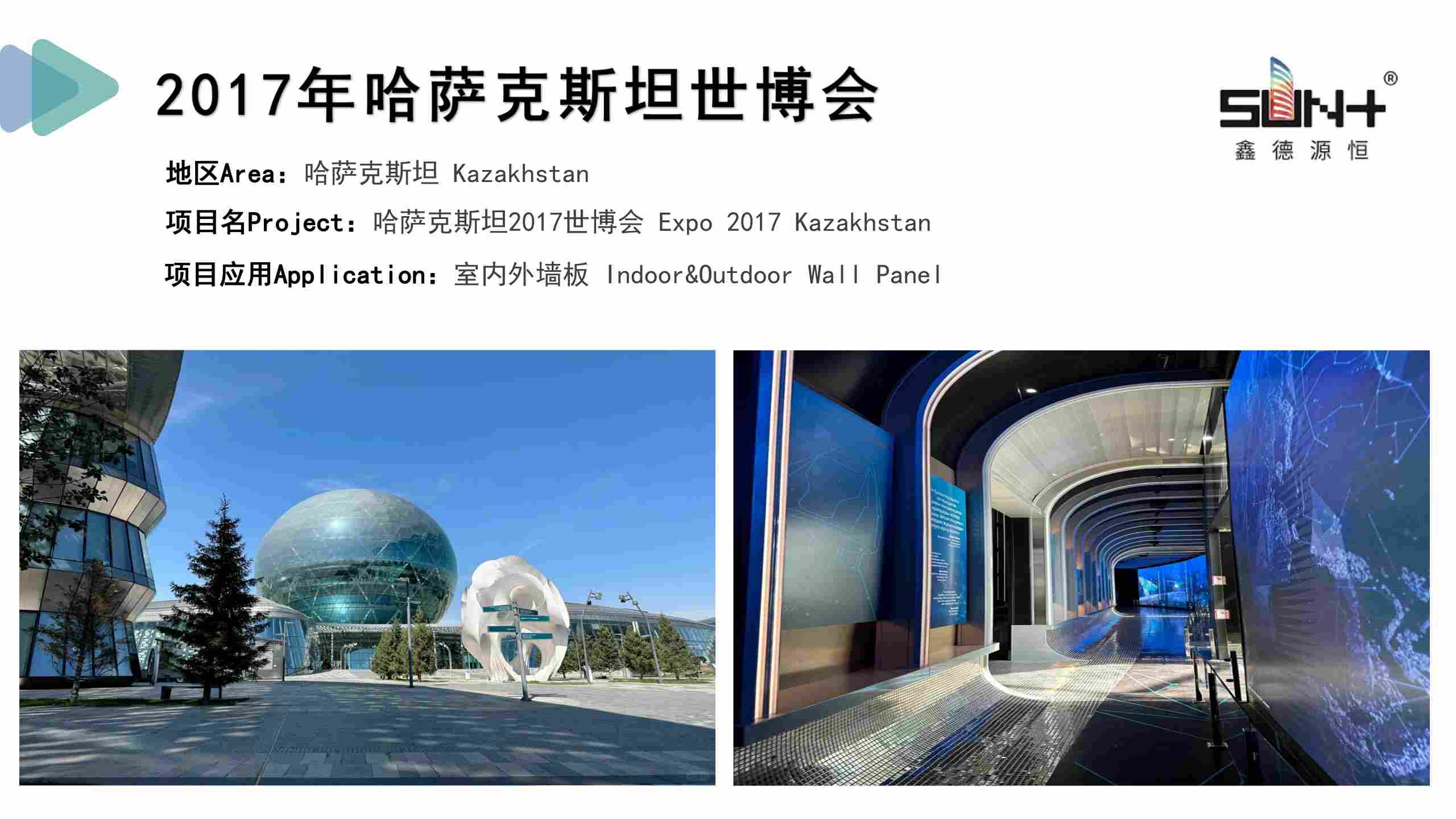

Expo 2017 Kazakhstan

Premium HPL wall panels were featured at Expo 2017 in Kazakhstan, showcasing the versatility and aesthetic appeal of SUN PLUS materials for international exhibitions.

Canadian International School Dubai

SUN PLUS wall panels were installed at Canadian International School Dubai, providing durable, safe, and aesthetically pleasing surfaces for educational environments.

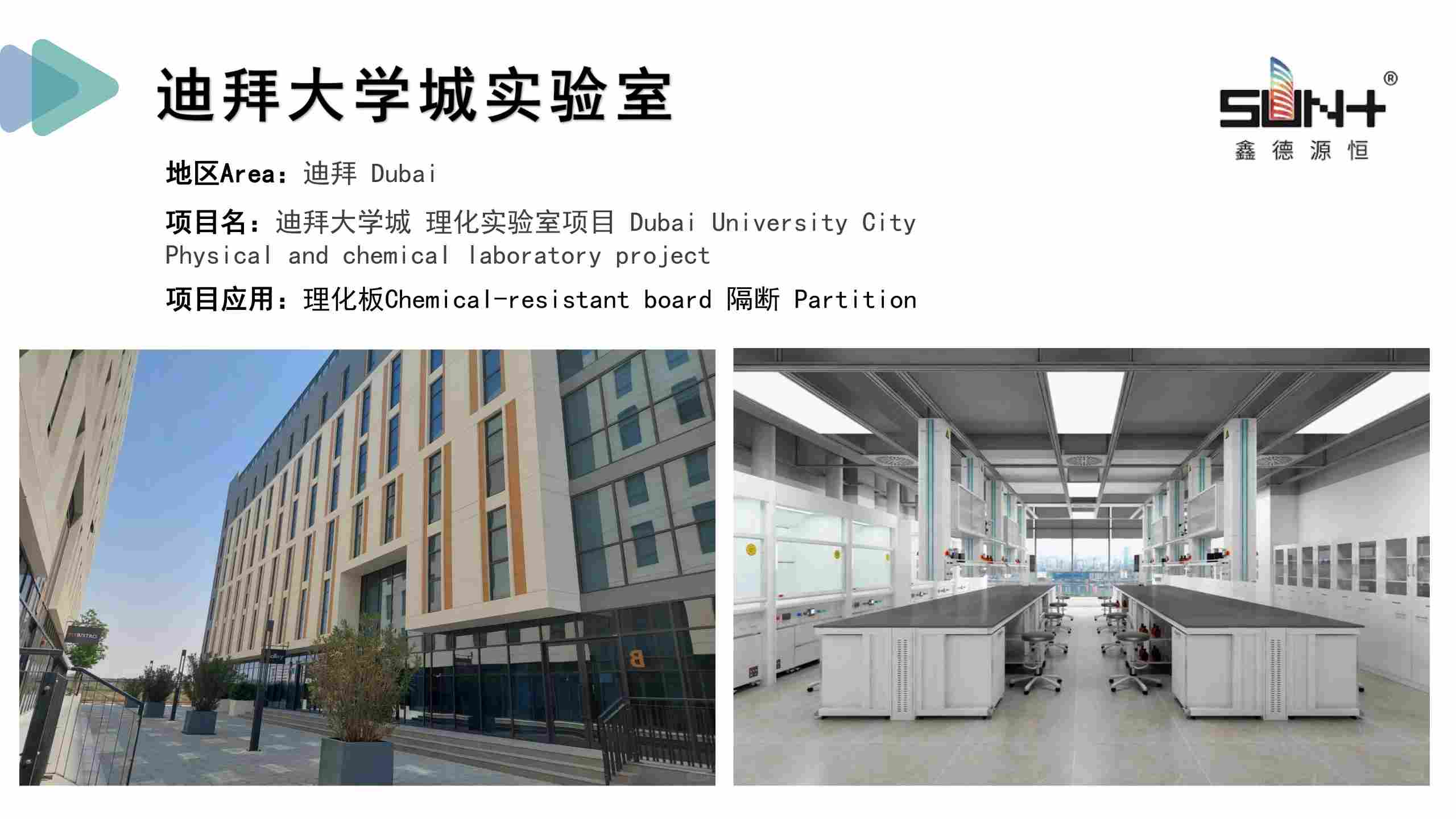

Dubai University City Laboratory

Chemical-resistant HPL boards and partitions were used in Dubai University City's laboratory facilities, ensuring safety and durability in demanding scientific research environments.

Lebanese University

HPL wall panels were installed at Lebanese University, combining durability with elegant design for academic facilities serving diverse educational purposes.

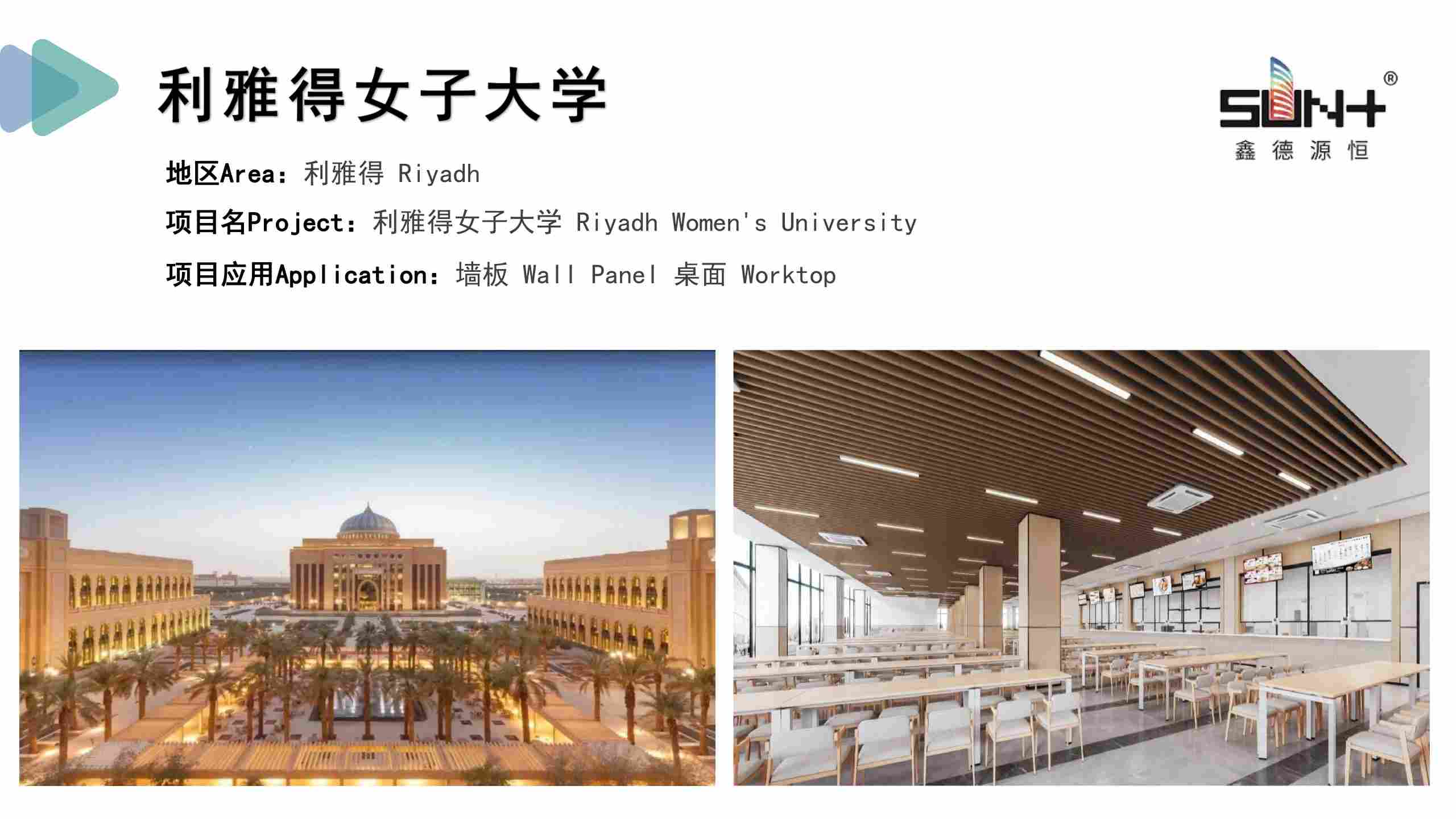

Riyadh Women's University

Premium HPL wall panels and worktops were selected for Riyadh Women's University, providing functional and aesthetically sophisticated surfaces for modern educational facilities.

Nicaragua Monte Hospital

Durable and hygienic HPL wall panels were installed at Nicaragua Monte Hospital, meeting healthcare facility standards for cleanliness, durability, and professional appearance.

Interested in This Product?

Request a free sample or get a custom quote for your project