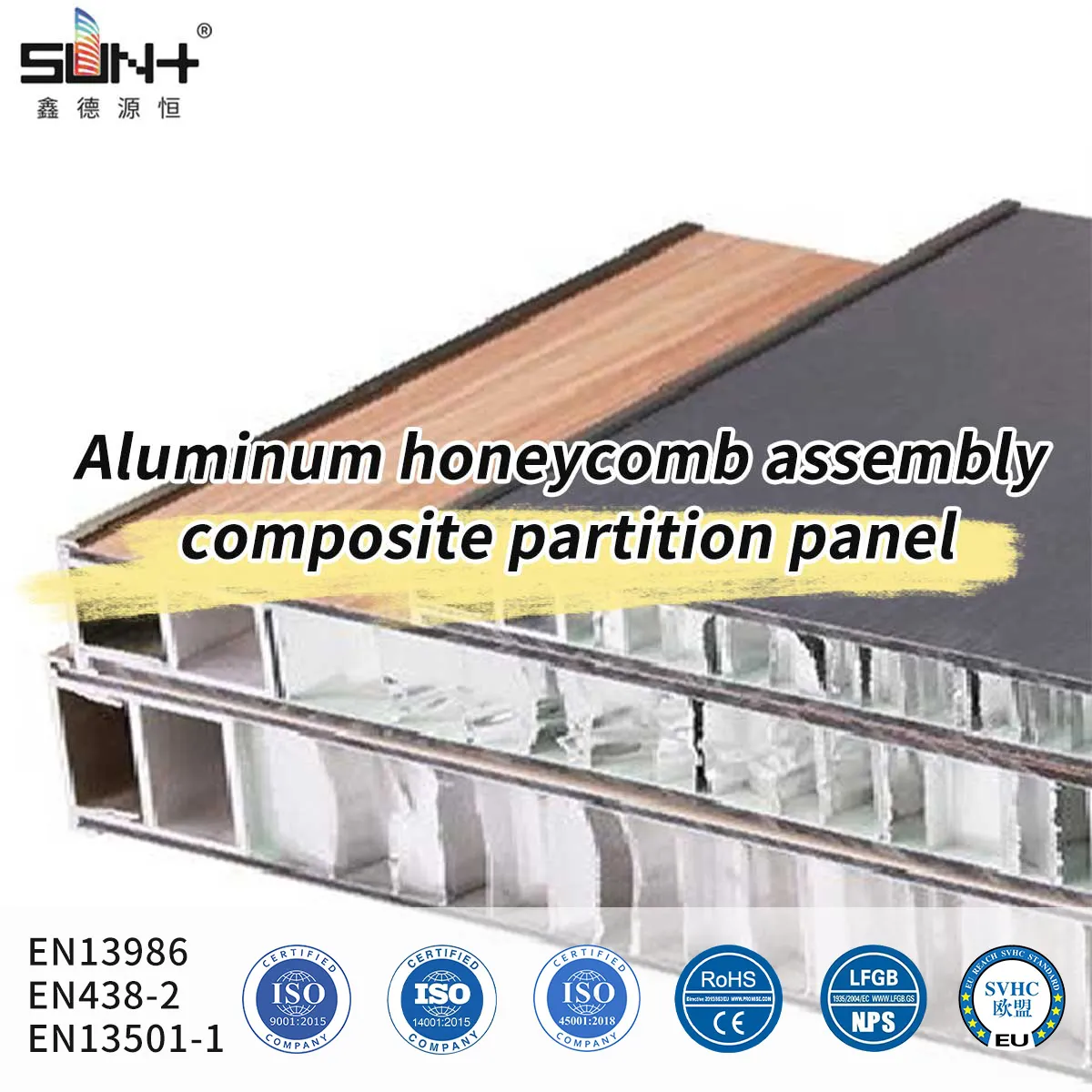

Honeycomb Core HPL Panels

Ultra-lightweight panels with excellent sound insulation

Quick Specifications

Product Overview

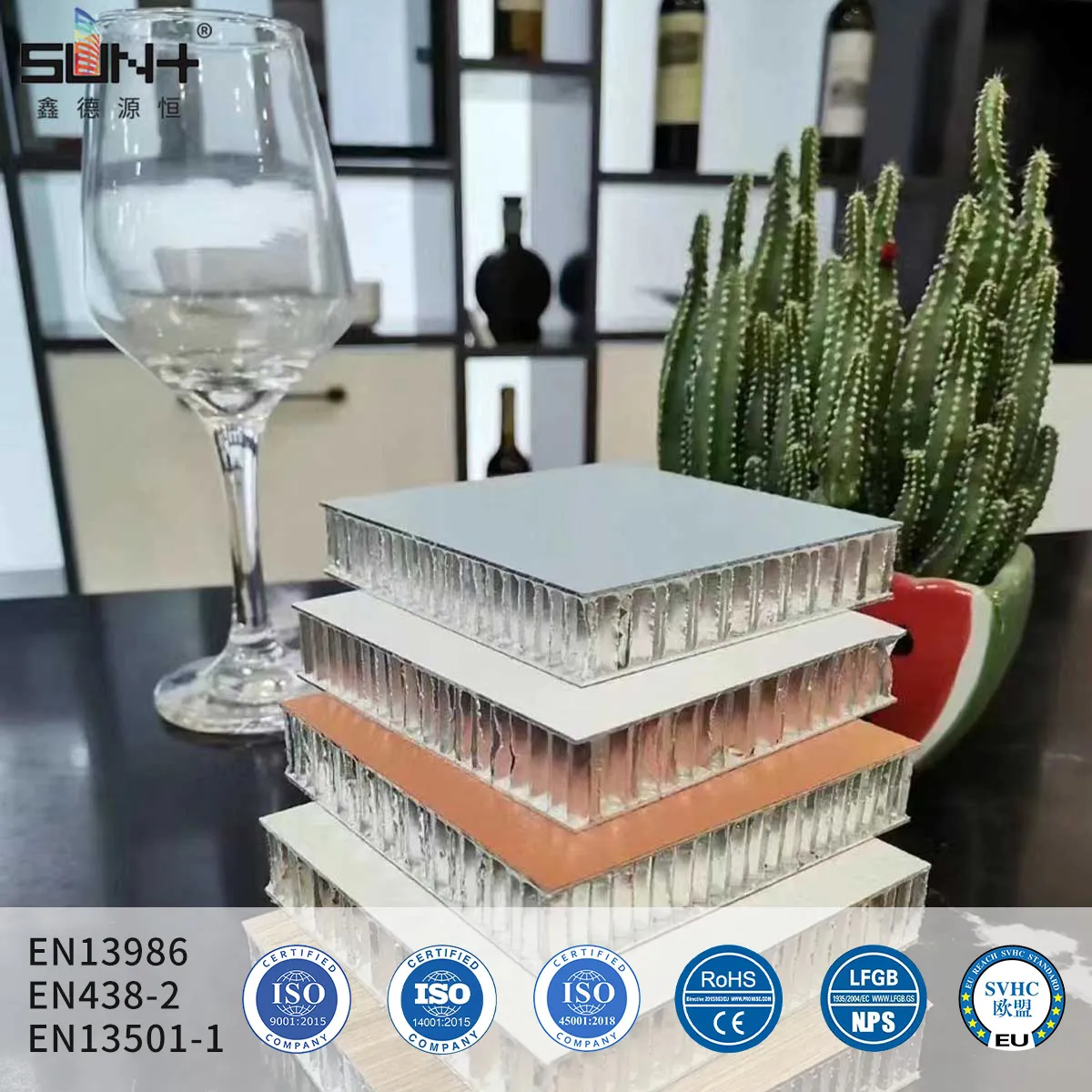

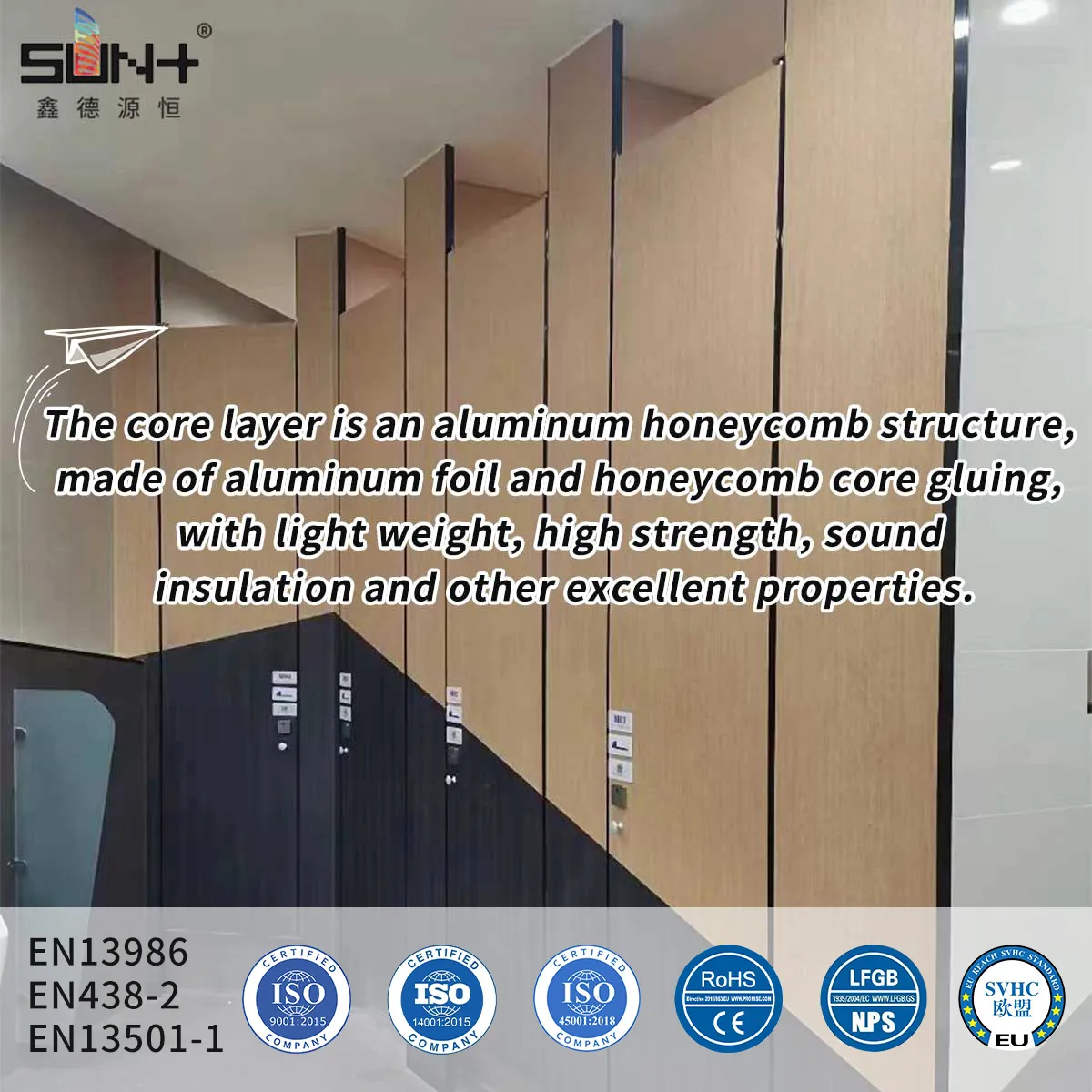

Honeycomb Core HPL Panels is an advanced composite panel combining HPL face sheets with an aluminum honeycomb core structure, creating an ultra-lightweight yet exceptionally rigid building material. The manufacturing process involves bonding high-pressure laminate skins (both sides) to an aluminum honeycomb core using structural adhesives under controlled pressure and temperature. The honeycomb core consists of aluminum foil (0.02-0.08mm thickness) formed into hexagonal cells (cell size typically 6-12mm), providing extraordinary strength-to-weight ratio. Panel thickness ranges from 10mm to 50mm, with the honeycomb core occupying 80-90% of the thickness while contributing minimal weight. Total panel density is remarkably low at 3-8 kg/m² (compared to 15-30 kg/m² for solid compact board of equivalent thickness), enabling easier handling, reduced structural load requirements, and lower transportation costs. The honeycomb structure provides exceptional flatness and dimensional stability even in large panel sizes (up to 1500×4000mm), preventing warping or sagging that occurs with solid panels. Excellent sound insulation properties result from the air-filled honeycomb cells which absorb and dampen acoustic energy. Thermal insulation is superior to solid panels due to the air gaps within the honeycomb structure. Fire resistance meets Class B1 standards (GB 8624) with aluminum core providing non-combustible barrier. The HPL face sheets offer all standard laminate benefits: scratch resistance, stain resistance, UV stability, weather resistance, and extensive design options including wood grains, solid colors, metallic finishes, and stone patterns. Ideal for curtain wall systems, exterior cladding, interior partition walls, ceiling panels, exhibition displays, transportation interiors (trains, buses, yachts), and any application requiring maximum rigidity with minimum weight. Meets international standards including ASTM C365 for flatwise compressive strength and EN 14509 for sandwich panels.

Technical Specifications

Physical Properties

| Thickness Range | 10mm - 50mm |

| Panel Density | 3-8 kg/m² |

| Honeycomb Cell Size | 6mm - 12mm |

| Maximum Panel Size | 1500×4000mm |

Performance Characteristics

| Flatwise Compression | >0.4 MPa (ASTM C365) |

| Flexural Rigidity | Excellent (minimal deflection) |

| Sound Insulation | 25-35 dB reduction |

| Thermal Conductivity | Low (excellent insulation) |

Quality Standards

| Fire Rating | Class B1 (GB 8624) |

| Sandwich Panel Standard | EN 14509 |

| Face Sheet | HPL per EN 438 |

Key Benefits

Ultra-Light

70% lighter than solid panels, easy handling

Sound Insulation

Excellent acoustic dampening, quiet spaces

Fireproof

Class B1 fire rating, safe construction

High Strength

Rigid structure, no sagging

Flat Surface

Perfect flatness for large panels

Easy to Install

Lightweight reduces labor

Eco-Friendly

Recyclable aluminum core

Cost Effective

Material and shipping savings

Real-World Case Studies

Proven Excellence in Global Projects

Dubai 2020 Expo

SUN PLUS HPL materials were used for outdoor cabinets and toilet partitions at the Dubai 2020 Expo, demonstrating excellent durability and weather resistance in high-traffic public spaces.

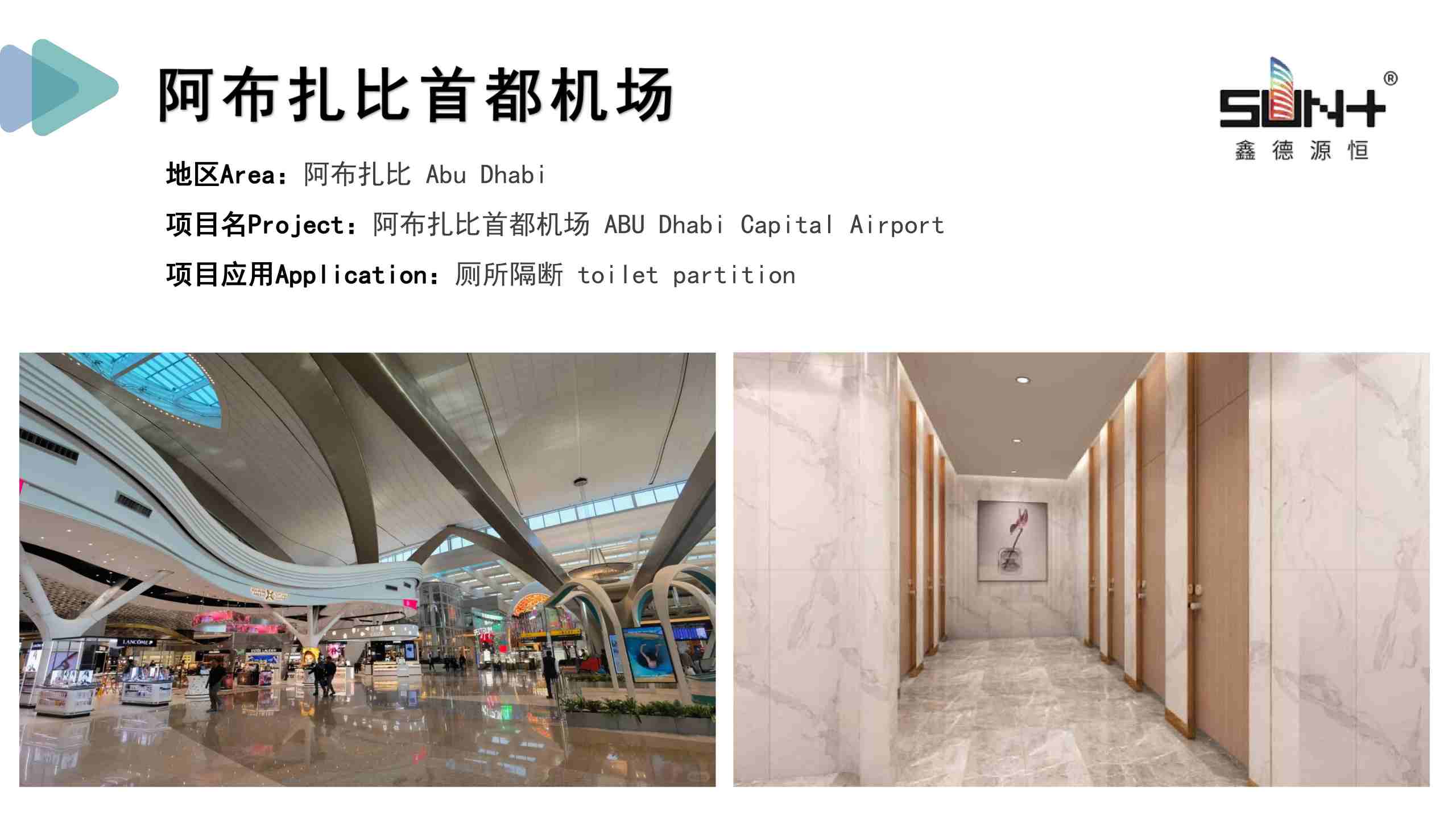

Abu Dhabi Capital Airport

Premium HPL partition systems were installed in Abu Dhabi Capital Airport's facilities, providing hygienic, durable, and easy-to-maintain surfaces for high-traffic airport environments.

Dubai Police Headquarters

SUN PLUS wall panels were selected for Dubai Police Headquarters, offering superior durability, fire safety, and professional aesthetics for government facilities.

Sharjah Police Headquarters

High-performance HPL partitions and cabinets were installed at Sharjah Police Headquarters, combining functionality with professional design for law enforcement facilities.

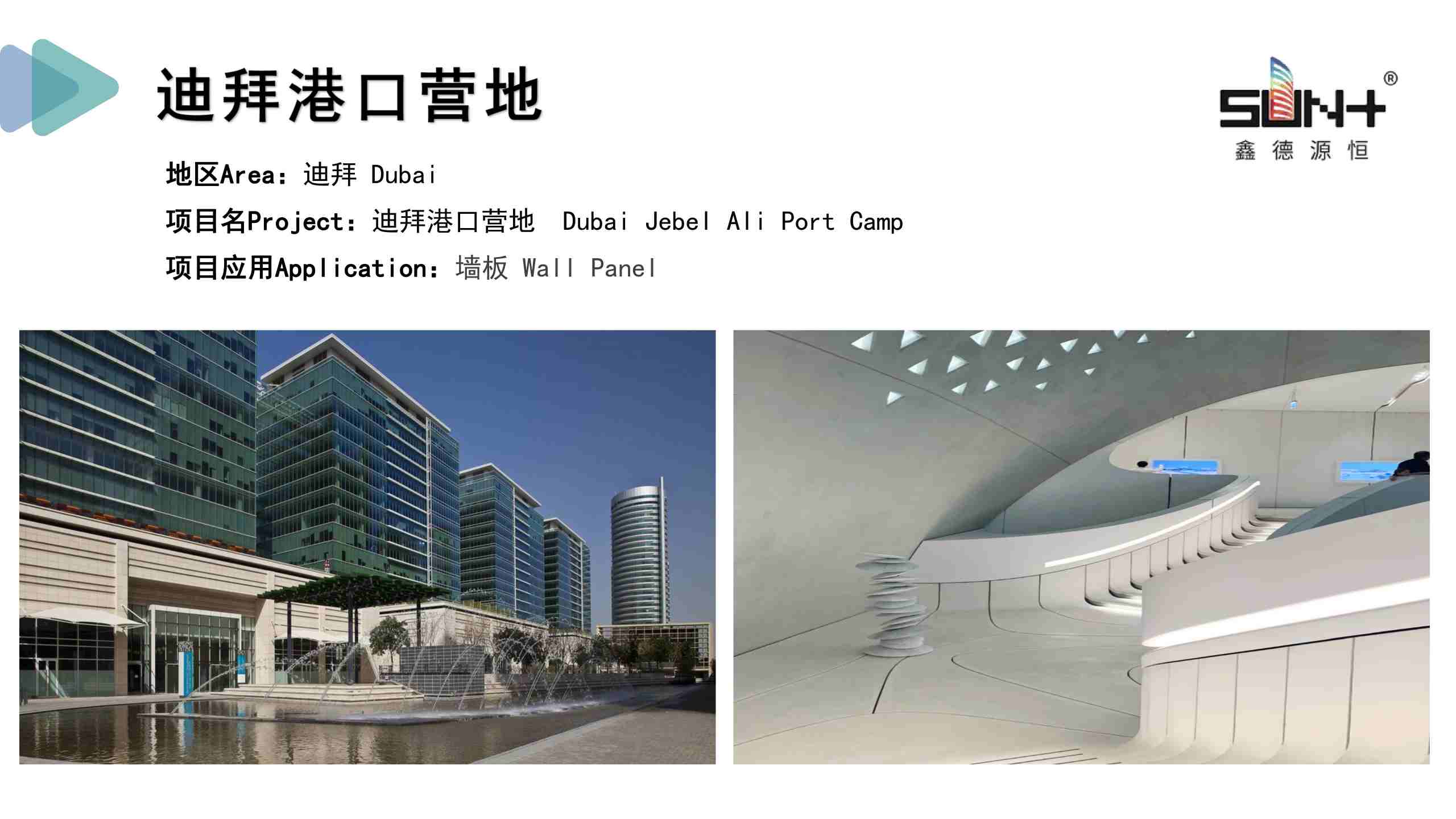

Dubai Jebel Ali Port Camp

Weather-resistant HPL wall panels were used at Dubai Jebel Ali Port Camp, providing excellent protection against harsh maritime and outdoor conditions.

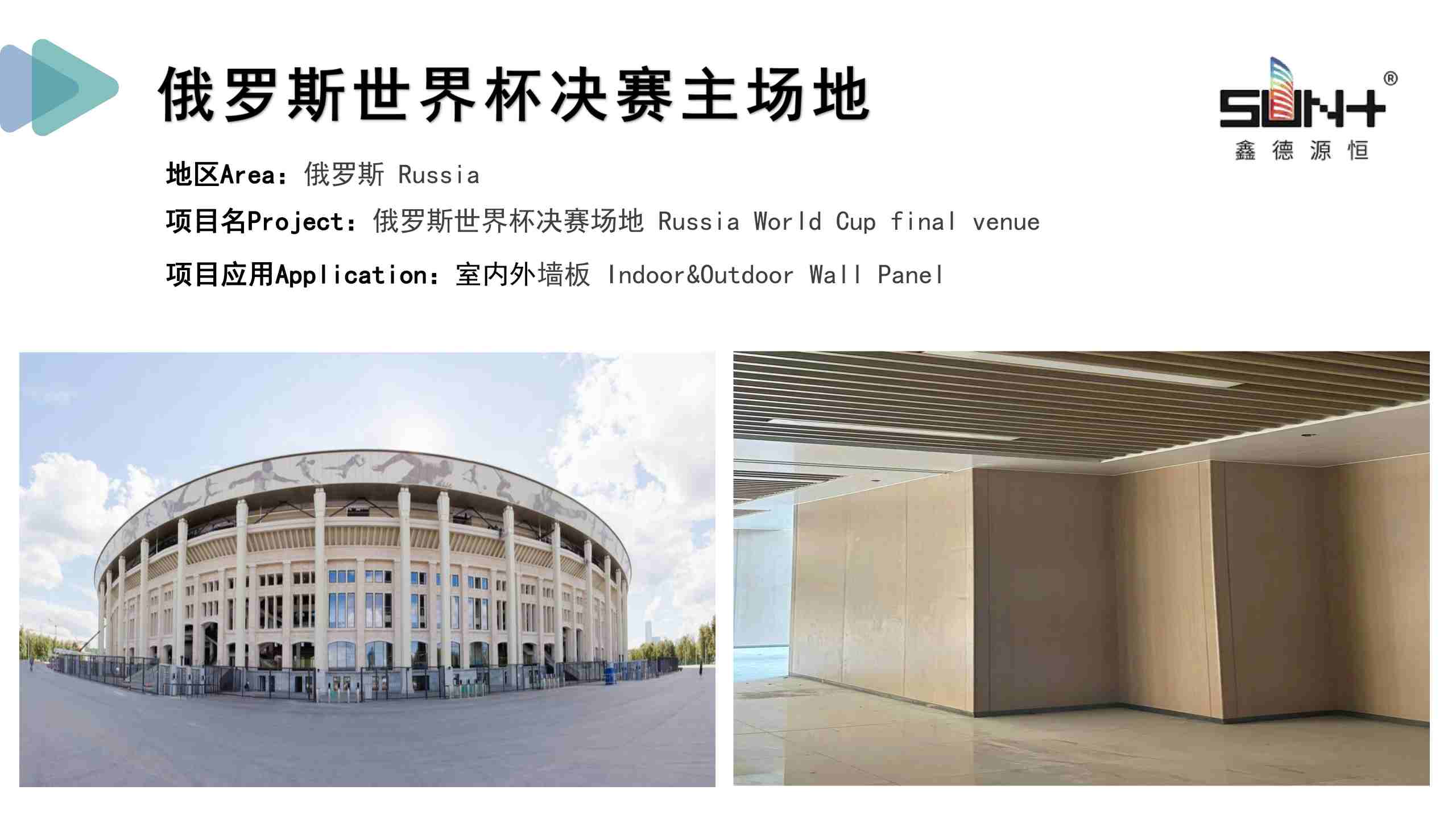

Russia World Cup Final Venue

SUN PLUS HPL materials were selected for the Russia World Cup final venue, meeting international standards for both indoor and outdoor applications with superior performance.

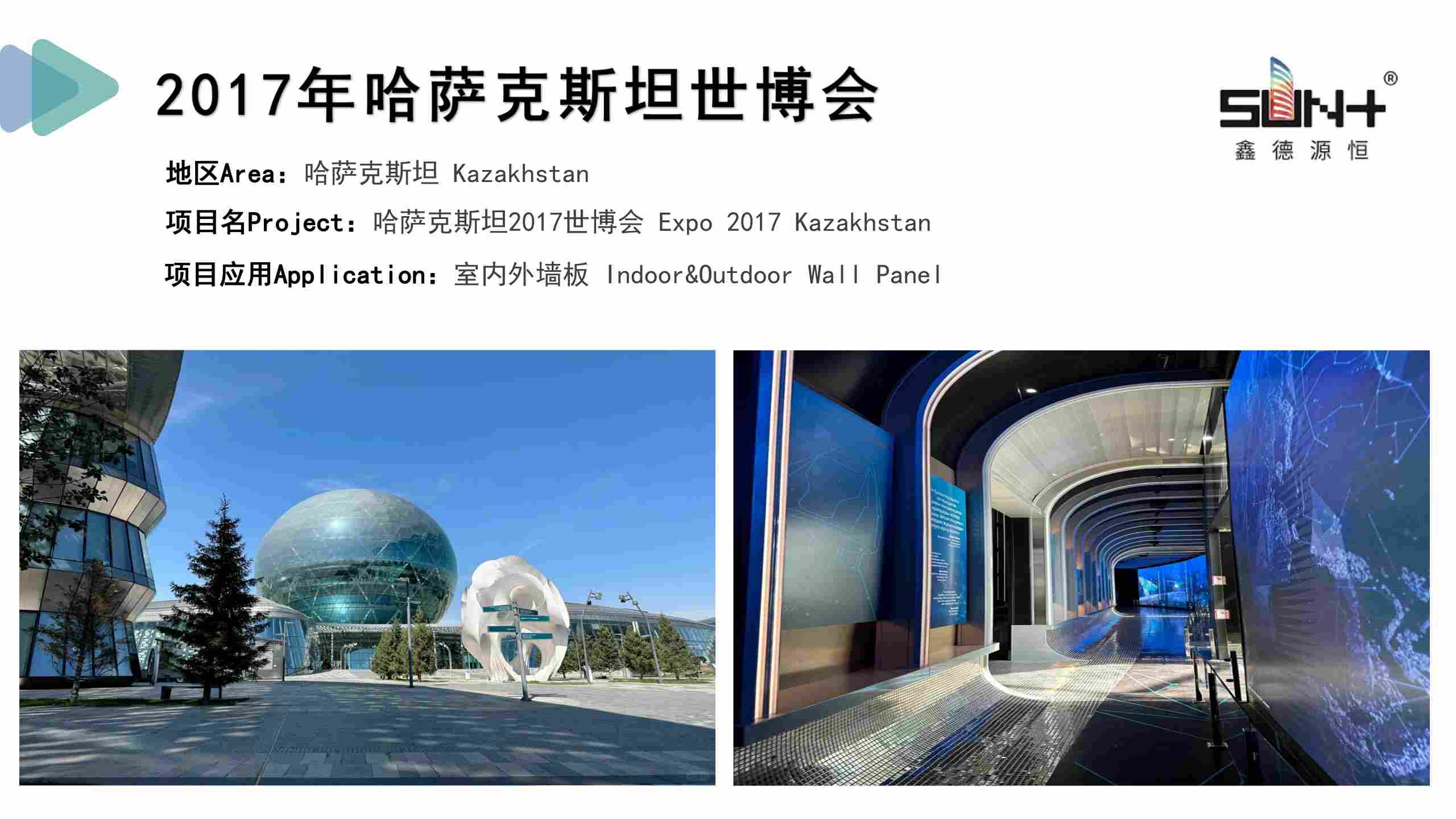

Expo 2017 Kazakhstan

Premium HPL wall panels were featured at Expo 2017 in Kazakhstan, showcasing the versatility and aesthetic appeal of SUN PLUS materials for international exhibitions.

Canadian International School Dubai

SUN PLUS wall panels were installed at Canadian International School Dubai, providing durable, safe, and aesthetically pleasing surfaces for educational environments.

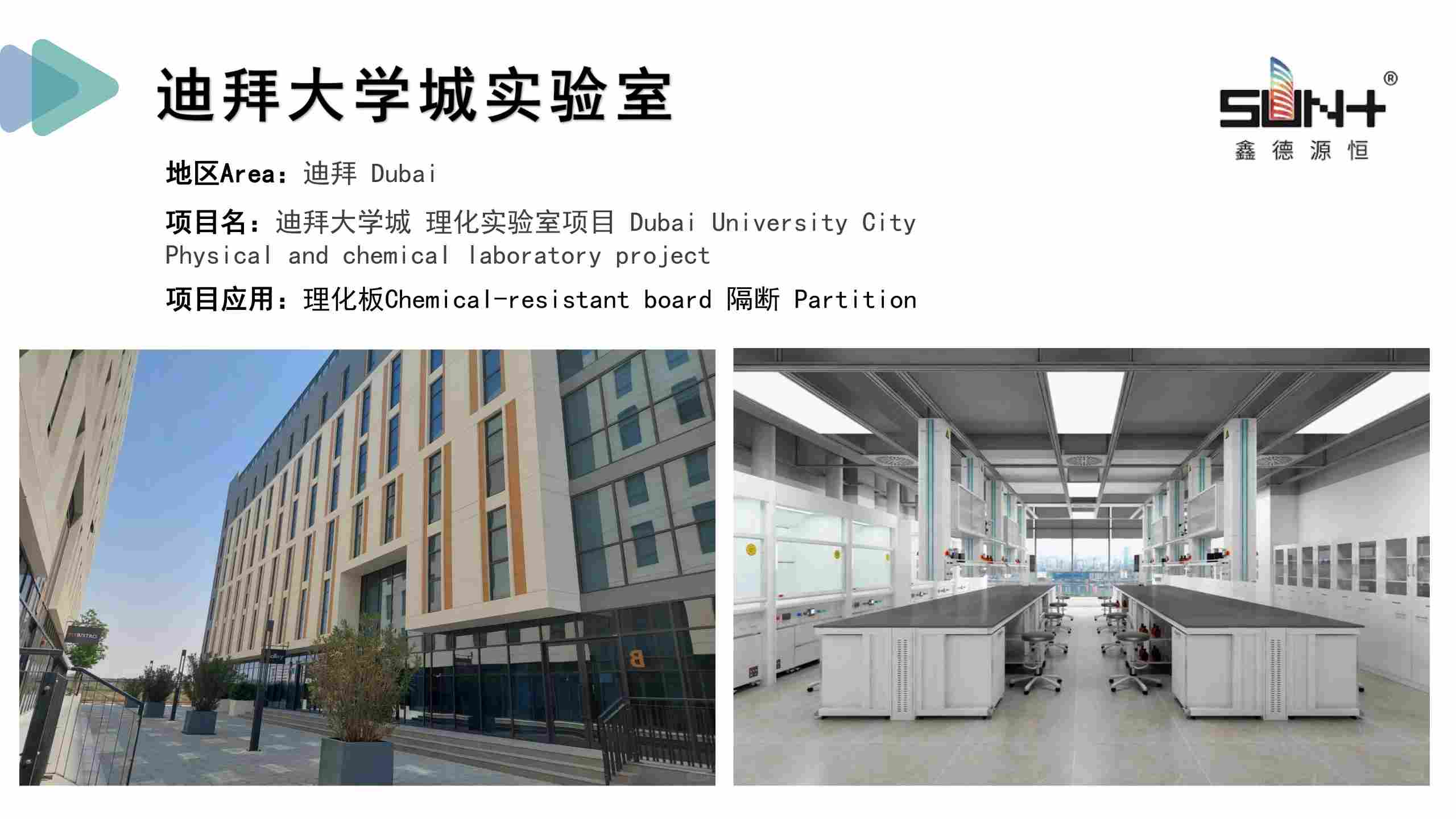

Dubai University City Laboratory

Chemical-resistant HPL boards and partitions were used in Dubai University City's laboratory facilities, ensuring safety and durability in demanding scientific research environments.

Lebanese University

HPL wall panels were installed at Lebanese University, combining durability with elegant design for academic facilities serving diverse educational purposes.

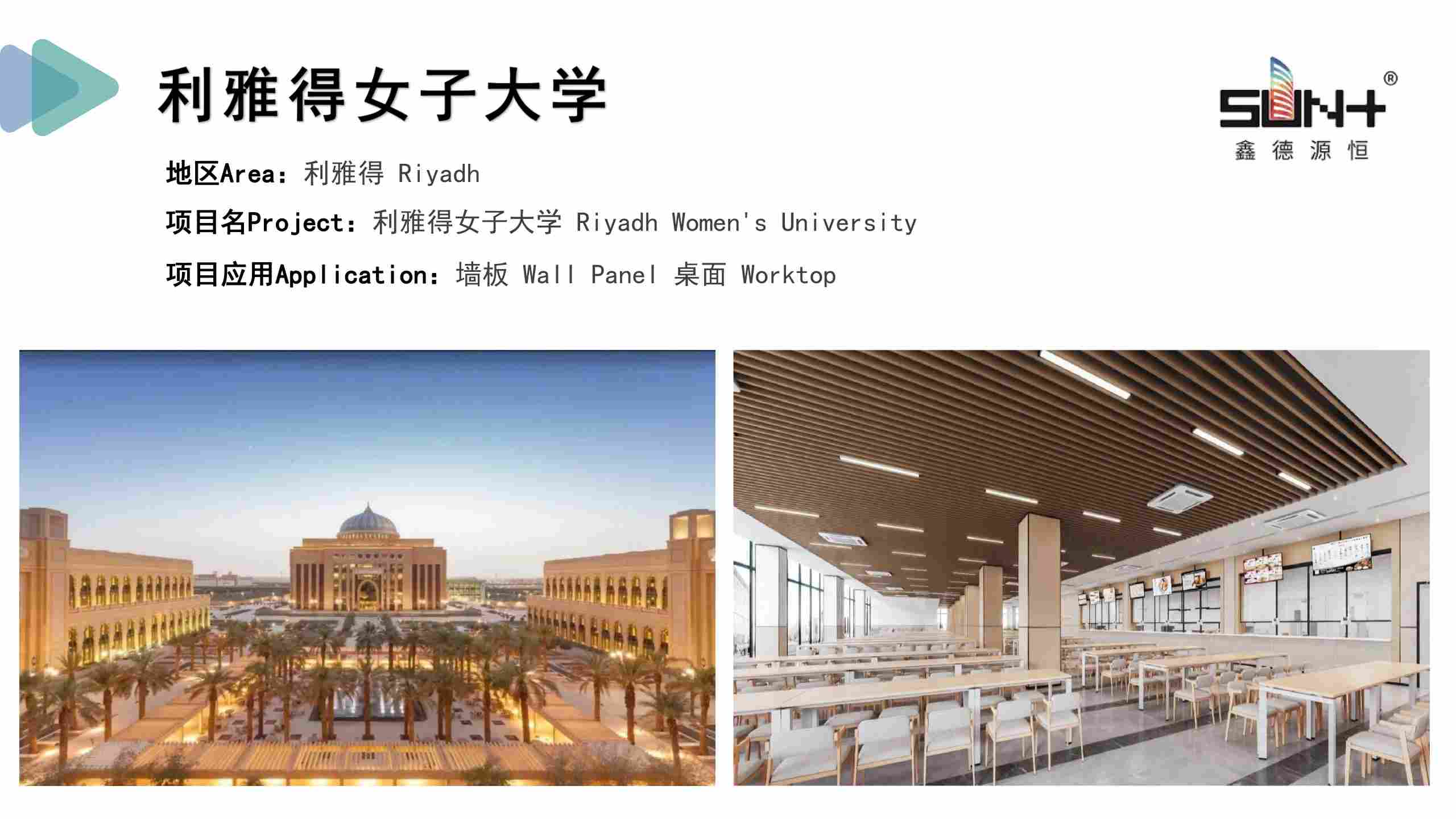

Riyadh Women's University

Premium HPL wall panels and worktops were selected for Riyadh Women's University, providing functional and aesthetically sophisticated surfaces for modern educational facilities.

Nicaragua Monte Hospital

Durable and hygienic HPL wall panels were installed at Nicaragua Monte Hospital, meeting healthcare facility standards for cleanliness, durability, and professional appearance.

Interested in This Product?

Request a free sample or get a custom quote for your project